By loading the video, you agree to YouTube's privacy policy.

Learn more

A Quantum Leap for Bulk Terminals

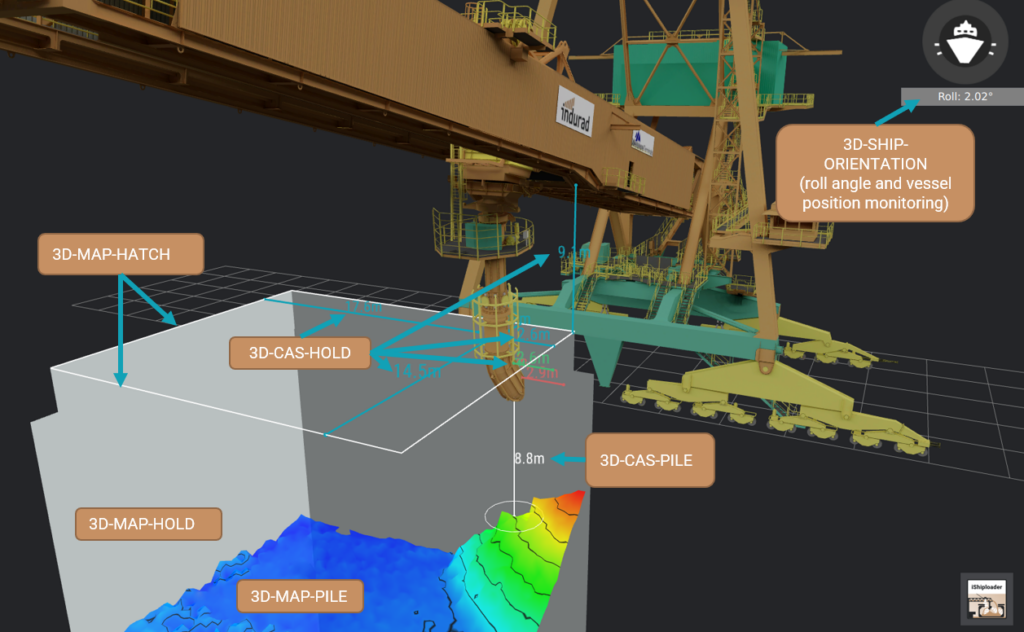

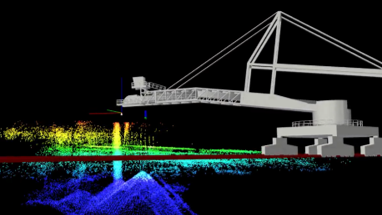

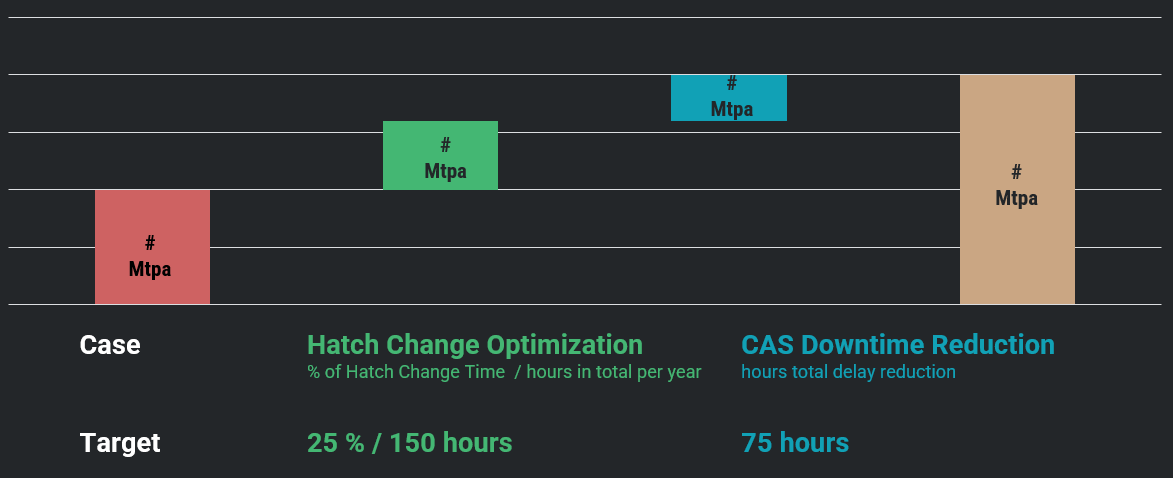

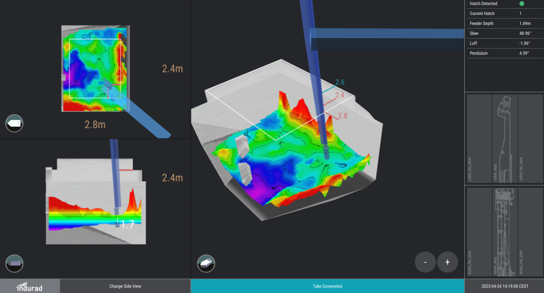

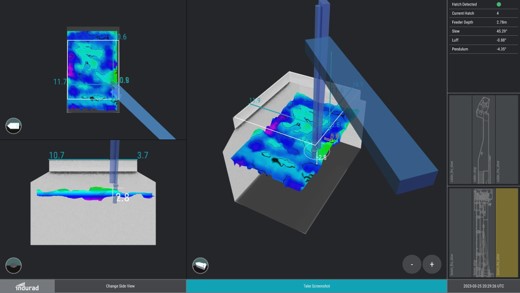

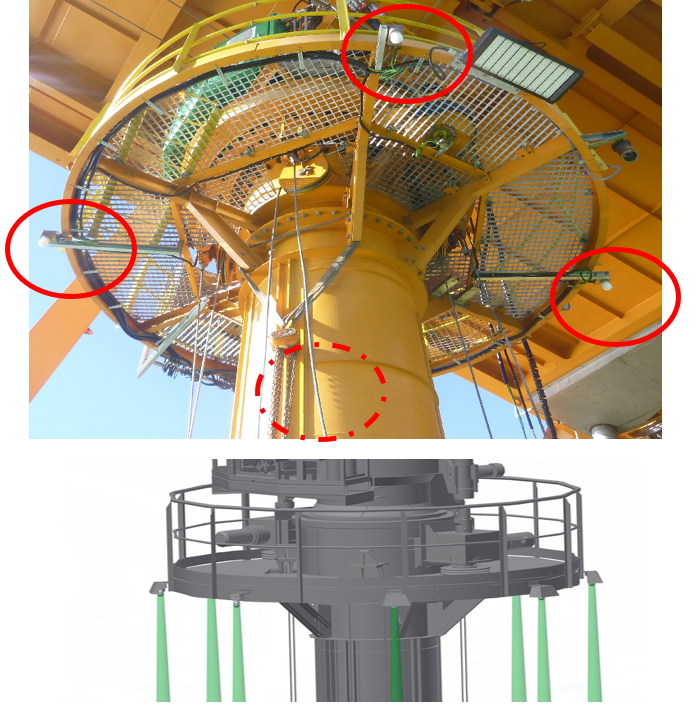

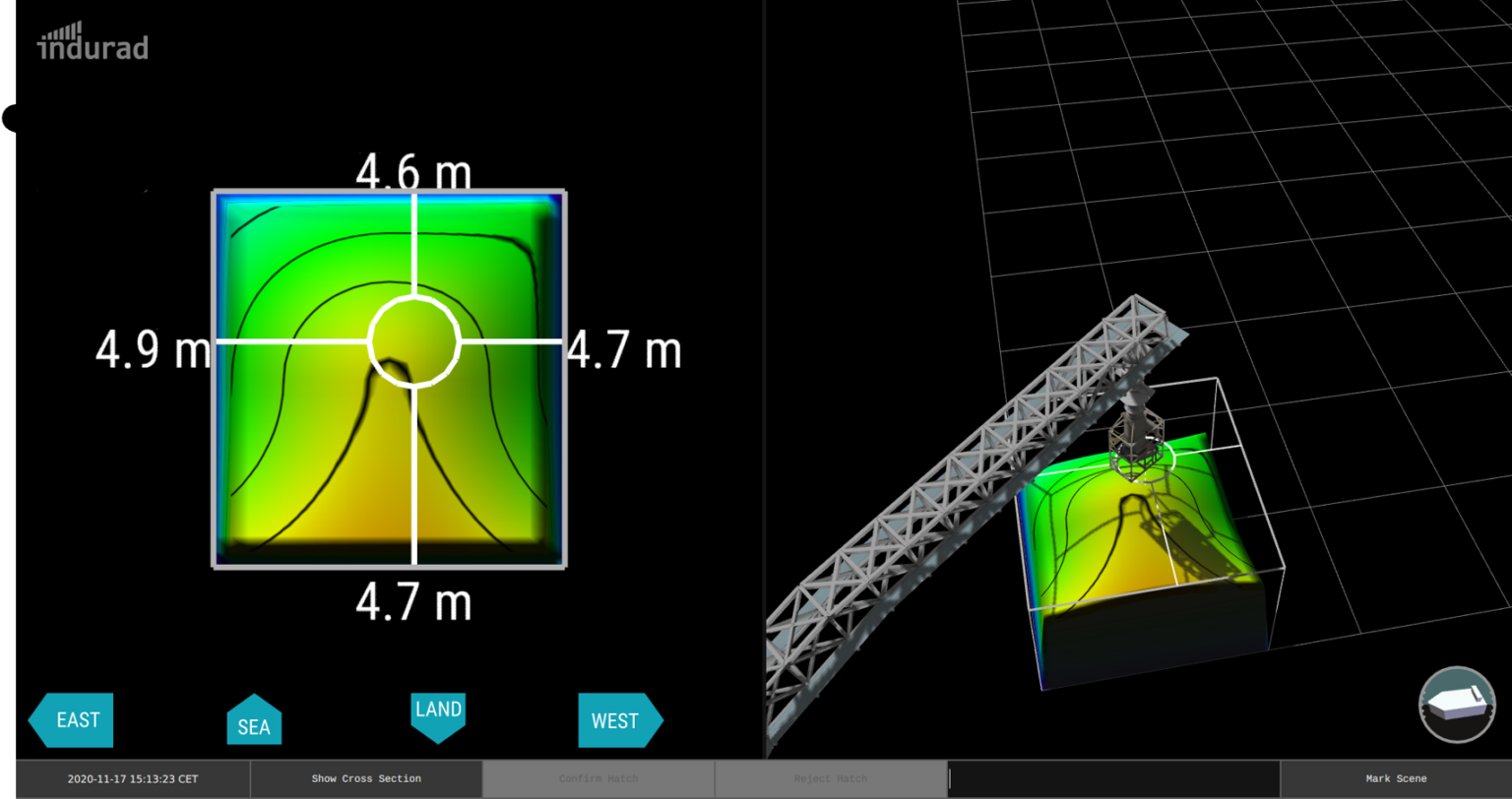

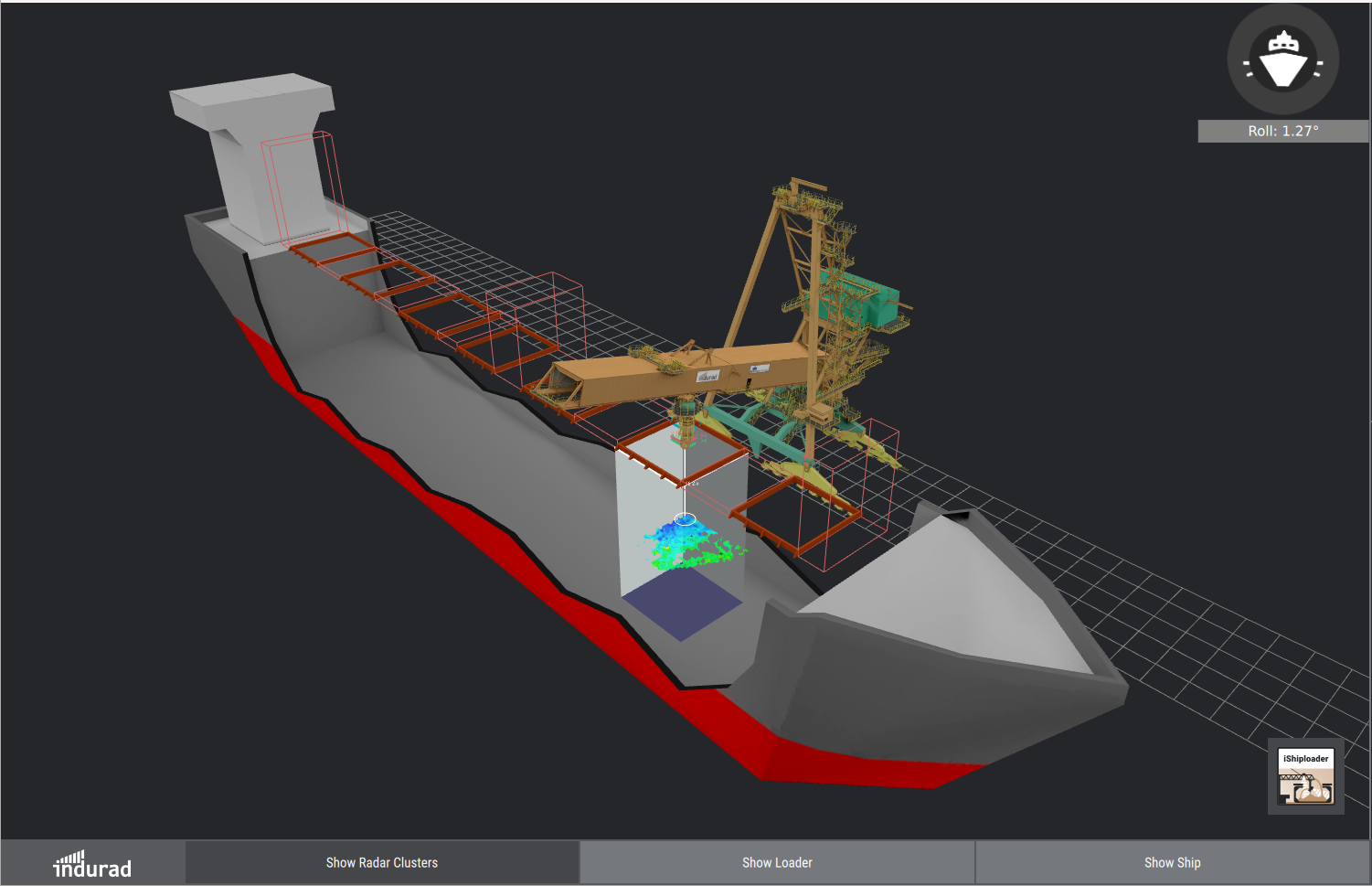

To improve port operations, EECV Rotterdam is using a combination of Indurad solutions.

Learn how the customer uses the solutions for individual benefits and how they are combined for a quantum leap in bulk terminal operations.