By loading the video, you agree to YouTube's privacy policy.

Learn more

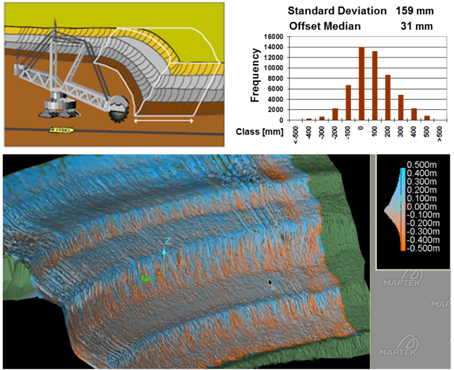

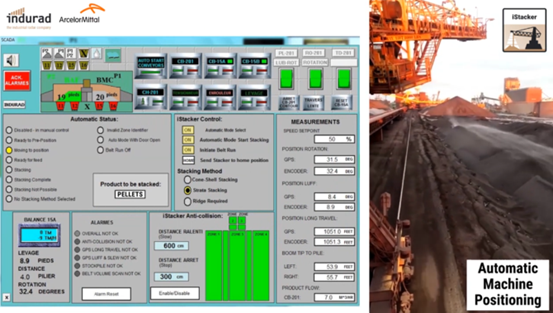

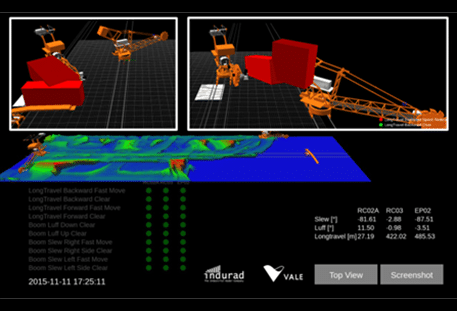

Cost down, revenue up

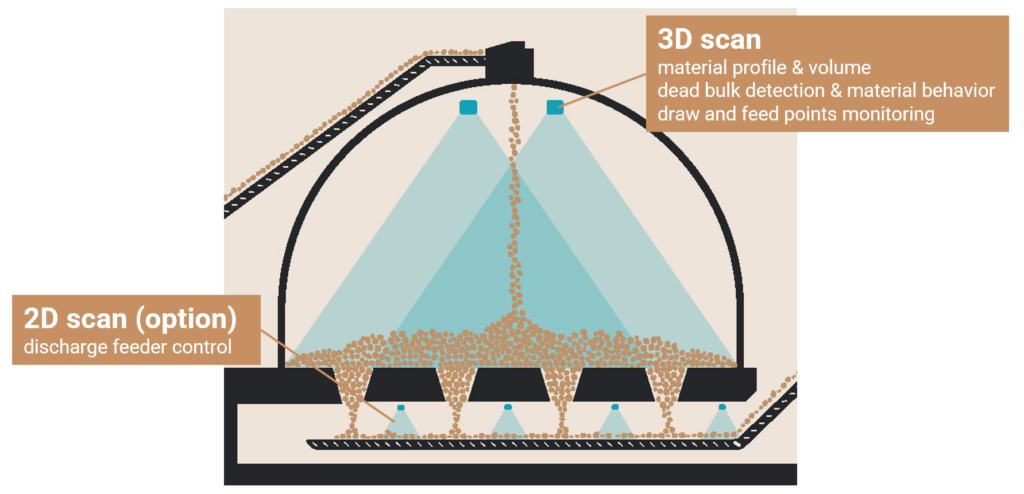

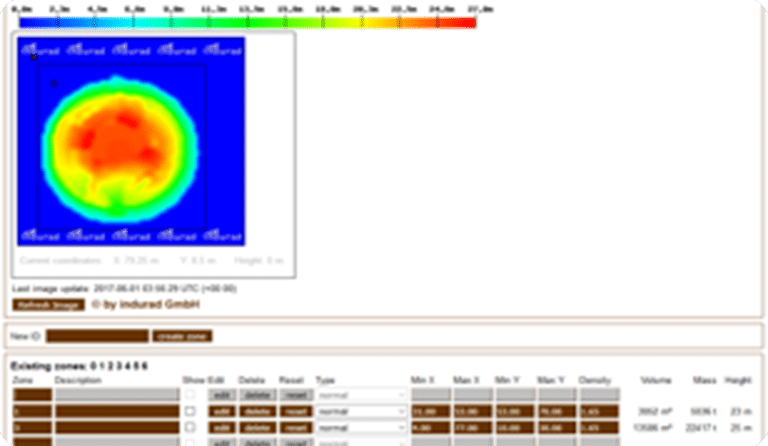

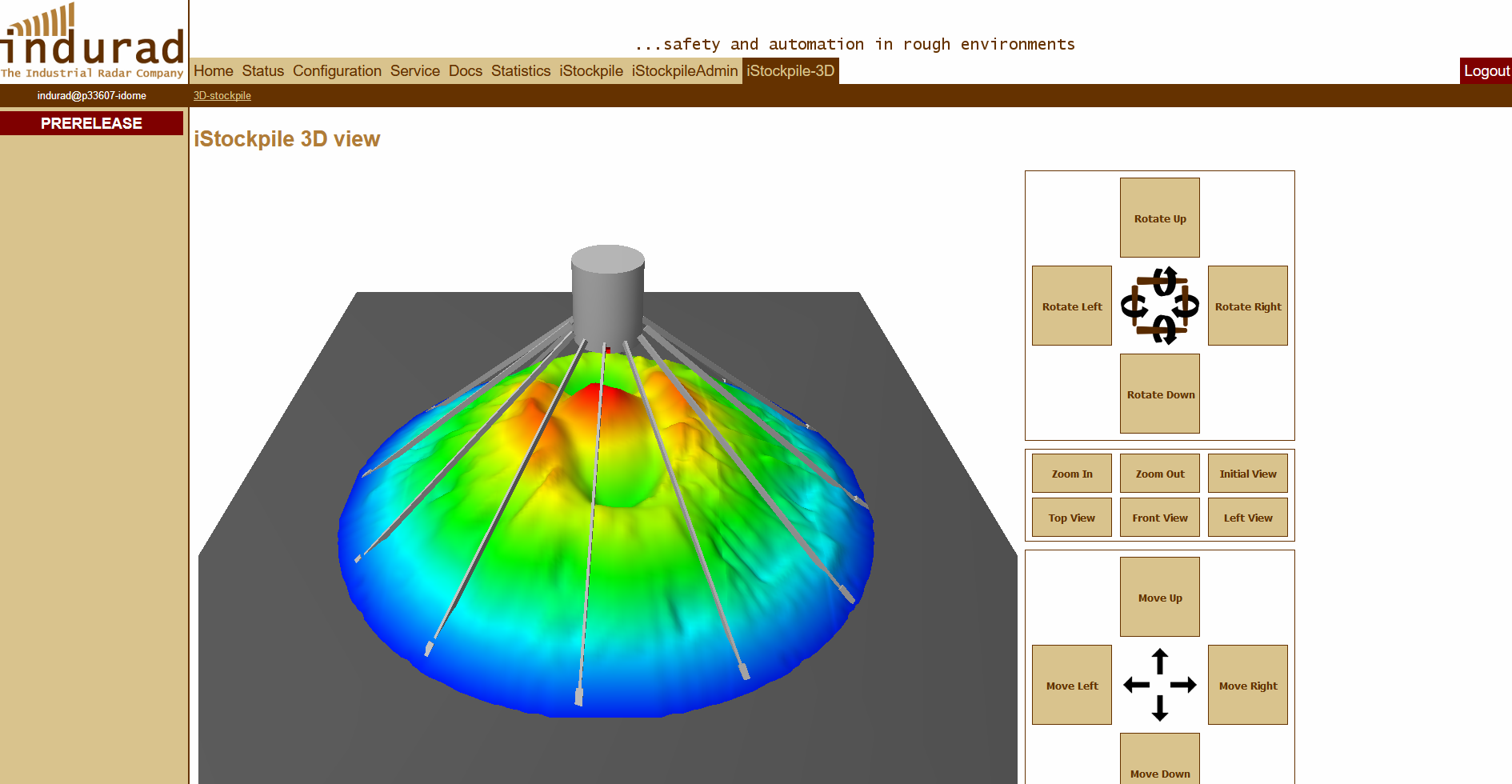

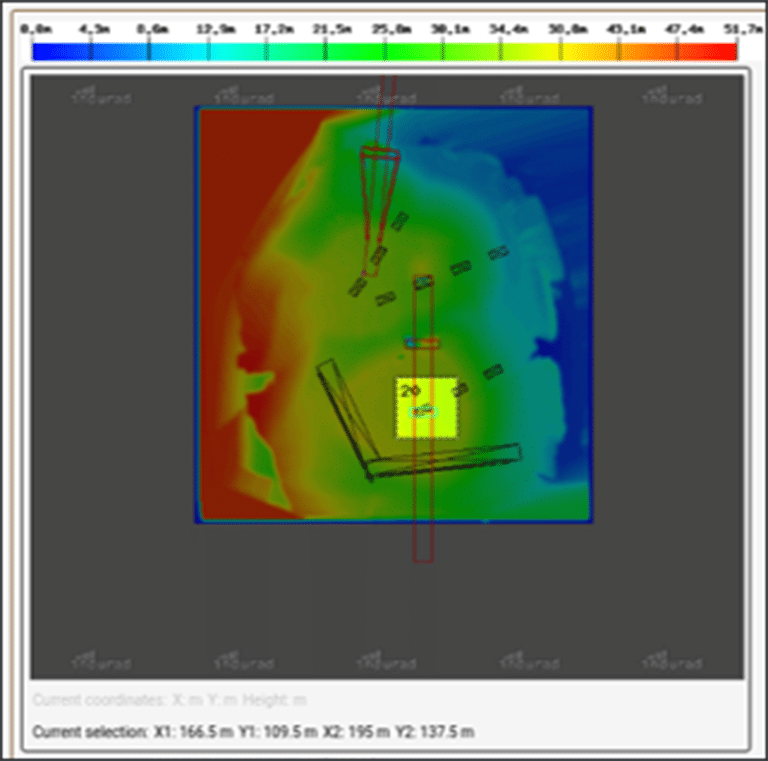

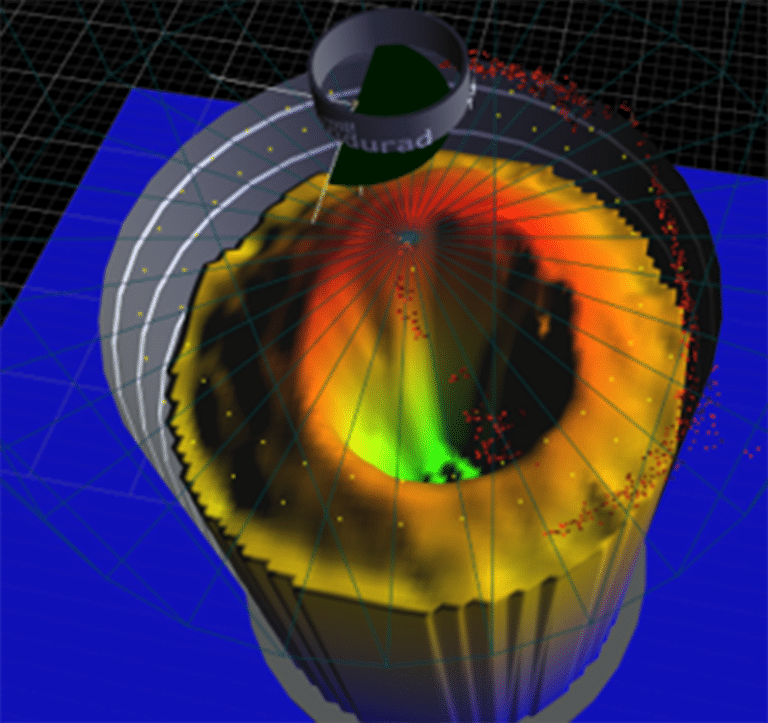

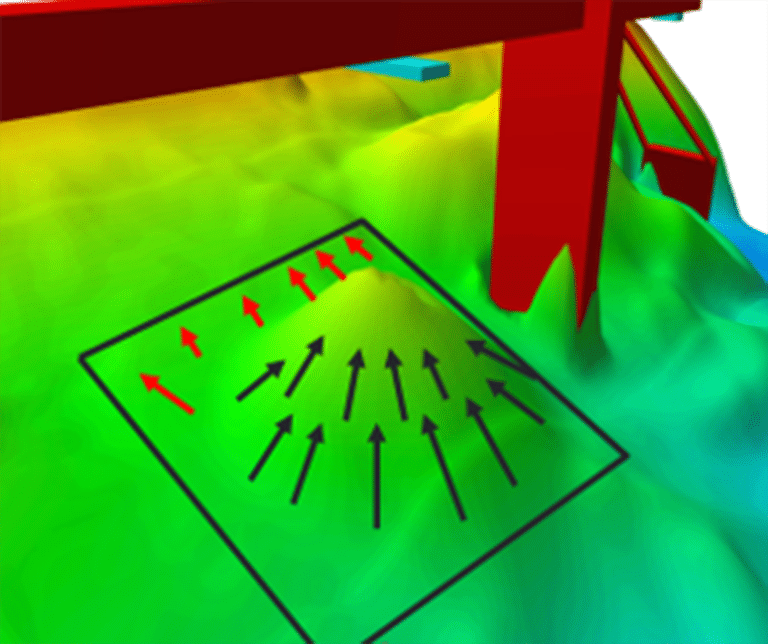

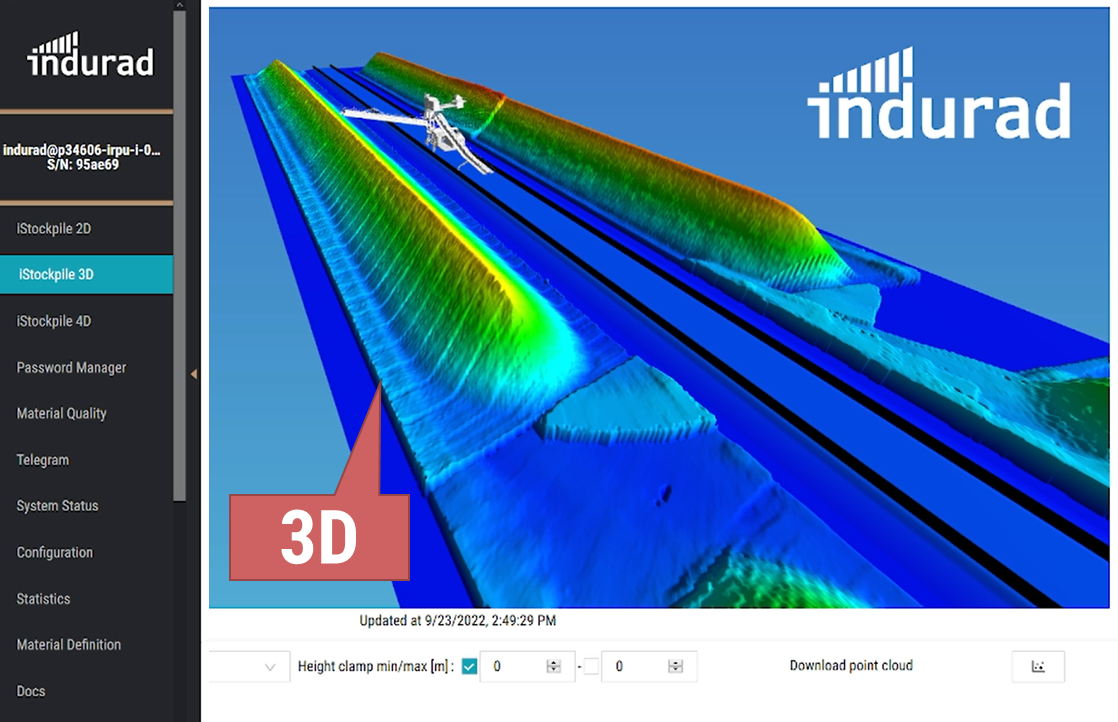

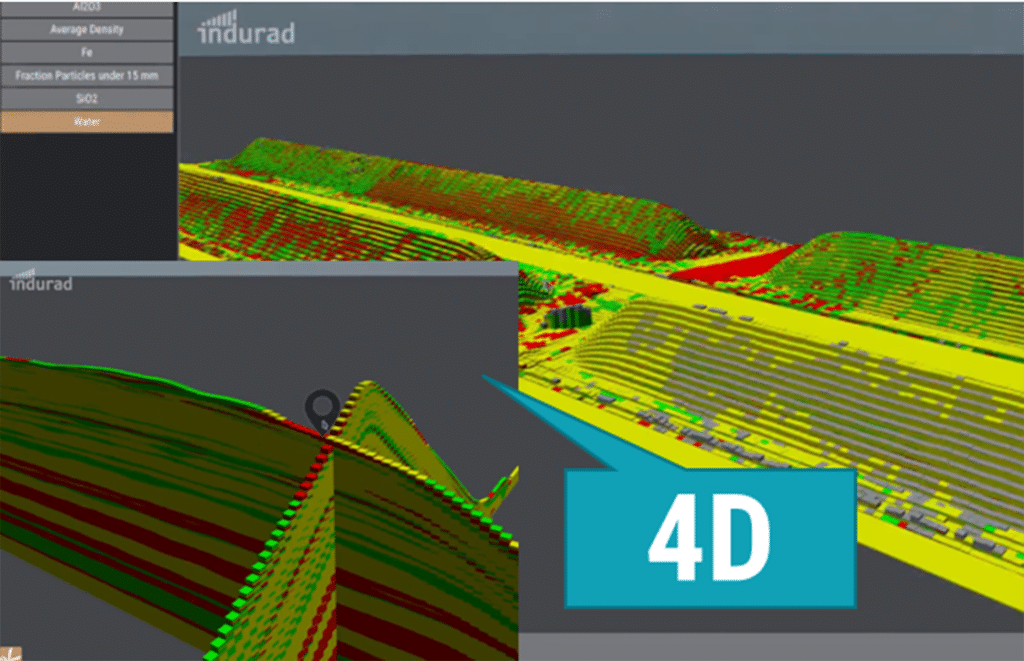

indurad is a leader in making mining and dry bulk handling or processing easier and more cost effective. Based on our radar technology we offer various solutions and also sensors with OEM interfaces such as ROS2.